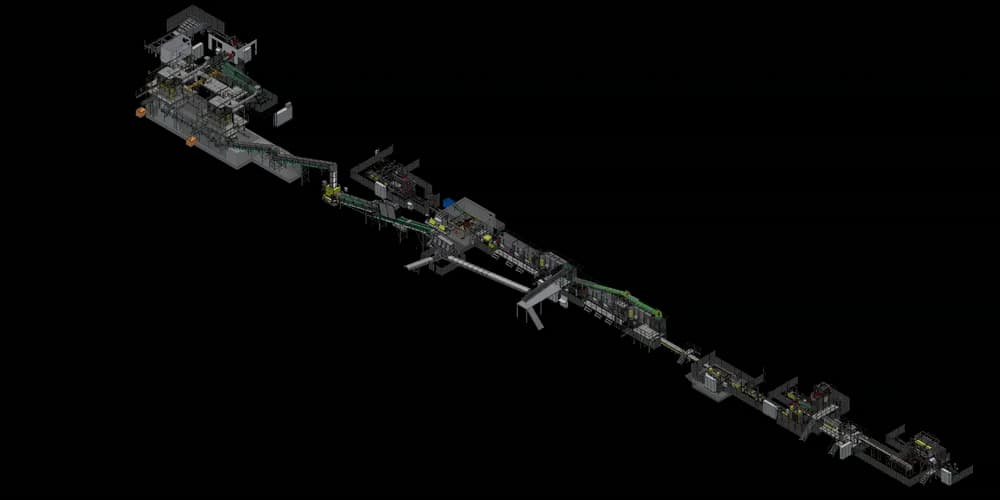

Acoustic Board Line

Acoustic WWCB production lines

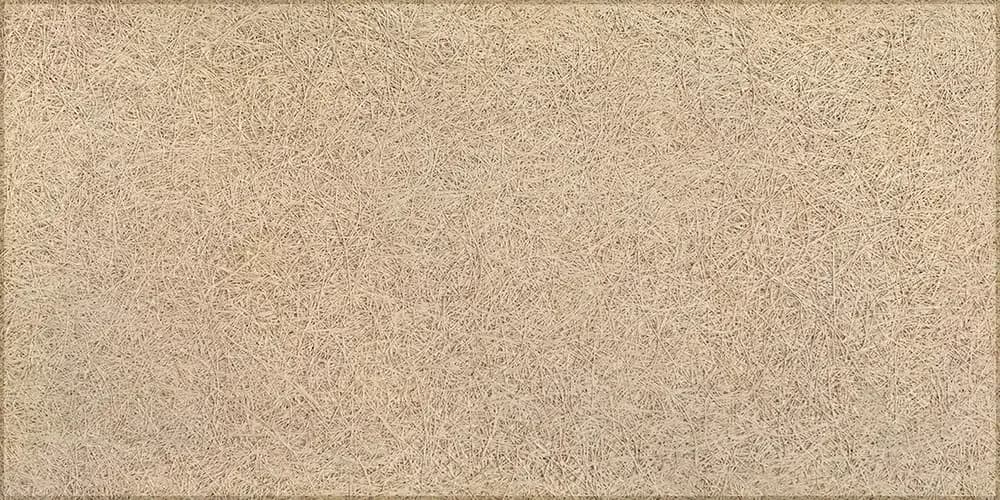

Eltomation is the global leader in automated production lines for acoustic Wood Wool Cement Boards (WWCB). Our high-capacity Eltomatic wood wool machine ensures precise, high-quality wood wool, while the Forming Station guarantees even distribution for a consistent and visually refined finish. With only four supervisors needed per shift, our advanced system enables efficient, high-output production. These boards offer superior sound absorption, fire resistance, and sustainability, meeting modern building standards and supporting eco-friendly construction.

Rooted in Acoustic Boards

Key WWCB plant characteristics

-

capacity of up to 4.300 m² per shift (25 mm board)

-

plant size: approx. 210 x 84 m (for three shifts production)

-

board dimensions: 2400 x 600 mm

-

board thickness: 15 to 35 mm for acoustic boards

-

wood wool width: 1 / 1.5 / 2 mm

-

only 4 operators required on the Eltomation line

Why Choose Acoustic WWCB Boards

Acoustic WWCB boards are valued for their natural aesthetics and outstanding acoustic performance. Their open structure effectively reduces reverberation, creating comfortable, noise-controlled environments in:

-

Schools

-

Offices

-

Theaters

-

Public spaces

Advantages beyond acoustics

-

Fire- and moisture-resistant for long-term durability

-

Emission-free, made only from natural ingredients

-

Customizable in texture, thickness, and edge profiles for architectural flexibility

With Eltomation’s advanced technology, these high-quality acoustic boards can be produced efficiently and sustainably.

Expansion opportunities

Interested in expanding your production capabilities? With slight additions to the line, manufacturers can expand their product range with: