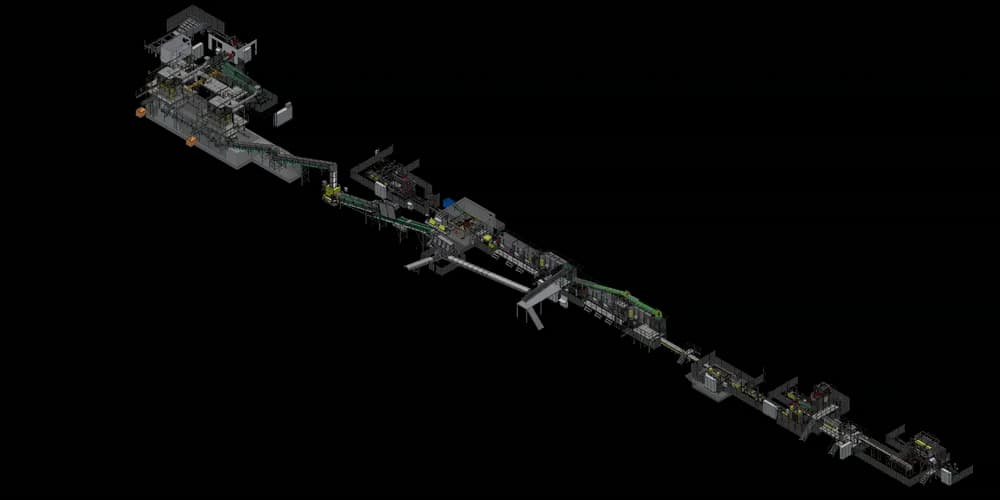

Construction Board Line

Production lines for Construction WWCB

With a slight modification to the standard production line, you can produce durable, fire-resistant WWCB boards widely used in construction. Their excellent fire performance makes them ideal for cladding applications, ensuring both protection and longevity. When reinforced, WWCB panels can also serve as roofing panels. These boards offer moisture regulation, thermal insulation, and acoustic benefits. Thanks to their natural composition and sustainable properties, WWCB supports healthy and eco-friendly building solutions for modern construction.

Rooted in Construction Boards

Key plant characteristics

-

capacity of up to 2.500 m² per shift (25 mm board)

-

plant size: approx. 210 x 84 m (three shifts)

-

line speed of 20,9 m/min.

-

board dimensions: 2000/2400 x 600 mm

-

board thickness: up to 100 mm for construction boards

-

wood wool width: 2 / 3 mm

-

only 4 operators required on the Eltomation line

FAQ Construction Boards

How do these boards perform in terms of fire resistance?

WWCBs are inherently fire-resistant, achieving classifications such as B-s1,d0 and A2-s1,d0 (non-combustible) according to EN standards. The inclusion of mineral wool, EPS or XPS cores enhances this fire resistance, providing added safety in building constructions.

What are the electric power requirements to operate a WWCB plant?

For the Eltomation production line alone, the estimated installed capacity is approx. 900 kVA. When adding finishing operations, total installed power requirements are estimated at 1800 kVA.

How can you promote sustainable products if cement is used in the recipe?

While cement production contributes to CO₂ emissions, the industry is actively working on solutions to reduce its impact. In WWCB production, more than half of the board’s mass consists of renewable wood and water, making it a more sustainable option than many traditional building materials. Additionally, the low density of WWCB means that less material is needed to cover a given volume, further improving its environmental footprint. In general, we can state that 1 m³ of wood used creates approx. 4 m³ of end product.

Our plants are designed to (optionally) use LC3 cement as a lower-carbon alternative to standard Portland cement without compromising board quality. In addition, many of our clients add a percentage of limestone to reduce the overall cement content, further lowering emissions while maintaining durability and performance.

Do you also provide technical assistance in the ramp up phase?

Yes. Several Eltomation personnel will remain on site for 6 weeks after first commissioning to make sure the plant runs smoothly, and local operators / supervisors are properly trained.